Stronger, more beautiful concrete floors at your fingertips!

Concrete is a time-tested flooring solution; trusted with the hardest tests any flooring project is put up to. But even concrete can be improved! Grind & Seal - the process of preparing concrete & installing epoxy resin on top of it - is the single best method of improving concrete flooring.

In this guide, we'll explore grind and seal. We'll get into what it is, why you need it, and how to install it. So read on! Don't settle for naked, vulnerable concrete.

What is Grind and Seal?

Grind and seal, polished concrete, epoxy resin sealed concrete, no matter what you call it - it's strong and reliable!

If you have concrete floors in your home, office or industrial space, you know how strong they can be. Even if you don't own concrete floors yourself, their reputation precedes them. So why do you need to make it even stronger?

That's because bare concrete isn't flawless. Incredibly strong, yes, but also prone to damage by chemicals, repeated exposure to heavy materials, chipping and more. But don't worry, because epoxy resin is the yin to concrete's yang. Together they create a long-lasting and durable flooring solution that's also beautiful!

The Role of Epoxy Resin in Flooring Solutions

What is Epoxy Resin?

Epoxy resin, a pivotal player in the realm of flooring solutions, is a versatile polymer characterized by its adhesive properties. Comprising epoxide monomers and a hardening agent, epoxy resin transforms during its cure into a robust material that flooring professionals swear by.

Why Epoxy Resin for Flooring?

-

Durability: Epoxy resin forms a tough, resilient surface, well-suited for high-traffic areas. On any measurement of strength, epoxy resin excels.

-

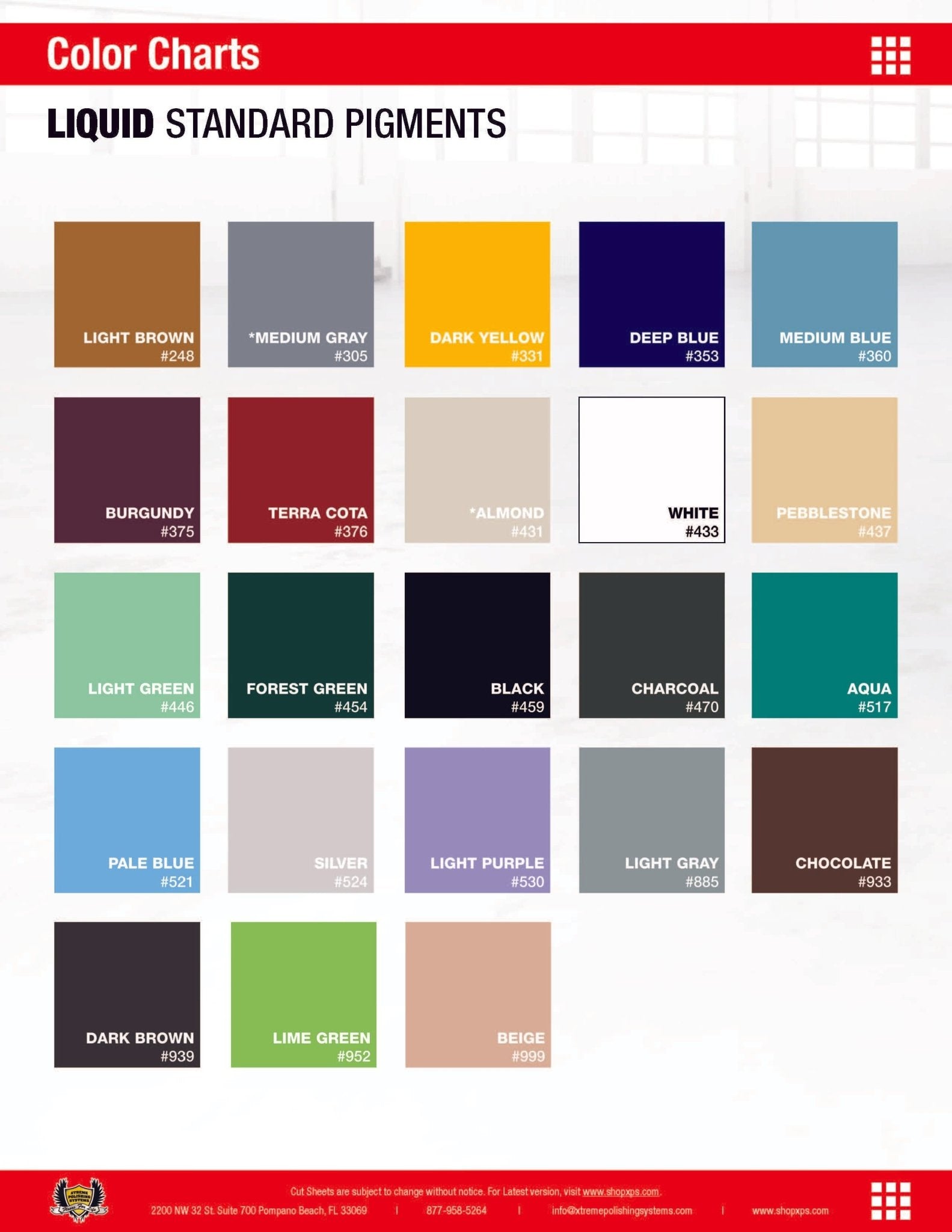

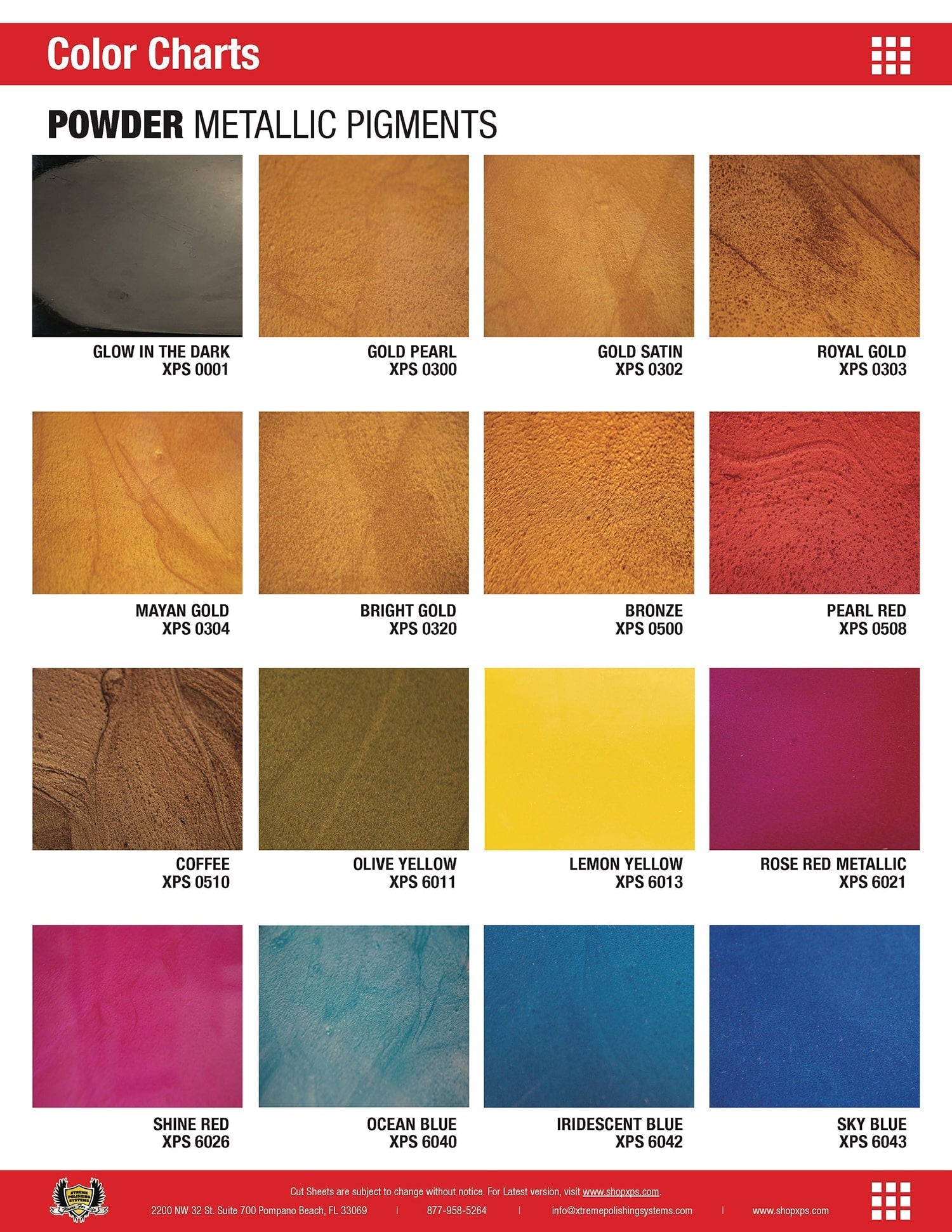

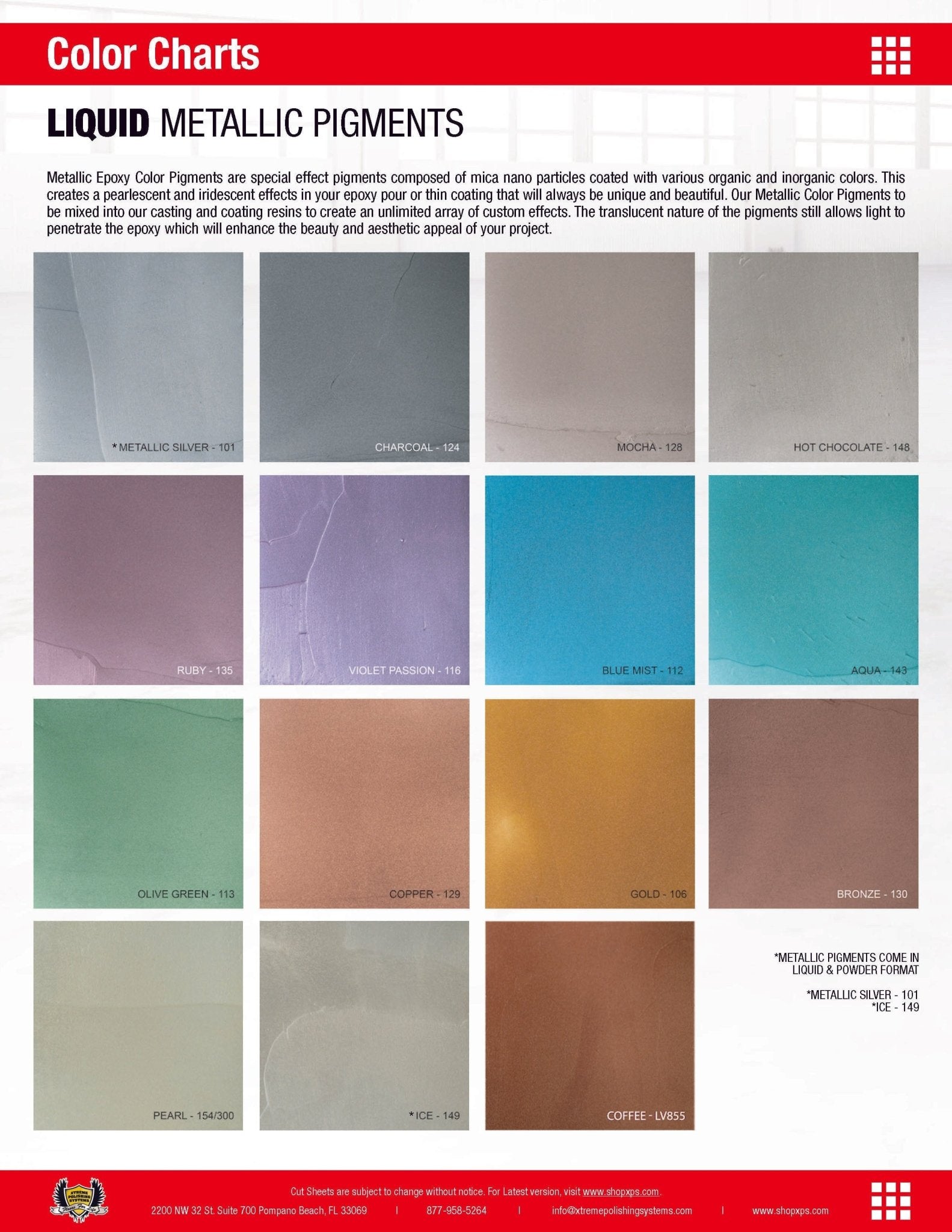

Aesthetic Versatility: The creative world is your oyster with epoxy resin. From glitters to pigments and more, epoxy's got it down!

-

Chemical Resistance: Epoxy's resistance to chemicals ensures the floor remains unaffected by spills and stains. You'll need this in any garage or industrial setting!

-

Easy Maintenance: A well-installed resin's smooth surface facilitates effortless cleaning, making it a practical choice for various settings.

When you combine epoxy resin into the Grind & Seal process, you're promised not only enhanced durability but also the freedom to fulfill any creative vision!

Tooling Up for Success

Half the success of any job relies on the right tools. Don't go out with an outdated toolkit! Stock up here at XPS.

Grind and Seal Installation: A Seamless Process

Step 1: Concrete Grinding & Leveling

Initiate the process by grinding the concrete surface meticulously using the Concrete Genie. What kind of grinder you need exactly depends on the job - even though the Concrete Genie is incredibly versatile, you may need something more specific.

We have an exhaustive guide on the options in concrete grinders here. Your goal with grinding should be to create a slightly rough surface for the resin solution to adhere to, and to fix and irregularities in the concrete.

Step 2: Cleaning and Surface Preparation

Thoroughly clean the surface to prepare it for subsequent treatments. Many contractors perform surface preparation their own way, so do some research!

Fundamentally, though, surface preparation should be simple, but thorough. Professionals used to recommend acid etching to prepare the surface. Recently, we've realized that mechanical preparation is actually the way to go!

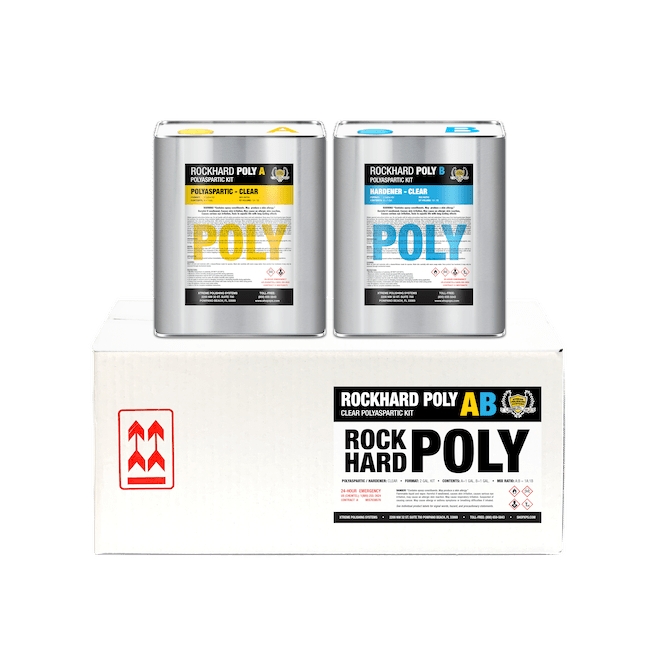

Step 3: Epoxy Resin & Sealing

Apply an epoxy resin sealer to the surface to shield it from stains and scratches. Everything you've done before this step has led to this. If your surface preparation is perfect, then your epoxy resin base will be that much stronger.

Take careful consideration of the installation. You want to maintain a sleek, level surface before the epoxy cures so that you won't have to perform intensive grinding after curing.

Step 4: Cure & Polish Epoxy Resin

Once the sealer is dried and cured, polish the installed system to give it a sleek and professional finish. After you've fully polished the floor, give it a good cleaning and you're done! Some mild cleanser and warm water should be just enough to give your epoxy resin floor a clean shine and gloss.

If you're more of a visual learner, EpoxyETC's video guide is a great resource to recap this whole process.

Conclusion

Bare concrete isn't just an eyesore - it's a potential hazard! Even if concrete is incredibly strong, it still needs help when it comes to the toughest of tests. Epoxy resin is your #1 solution to any issue. Learn how to install grind and seal floors & improve every concrete foundation for years and years to come!

At Xtreme Polishing Systems (XPS), we're the center for all things epoxy and concrete flooring. The best tools in the industry, at the best prices! Reach out to our technicians for personalized assistance on any job, at any time.