As time goes on, garage floors become damaged from foot traffic, tire marks, and chemical spills. In extreme cases, your once-beautifully installed garage floor may develop cracks and crevices.

Concrete garage floors wear away with time, succumbing this type of pressure. Garage floor Coating is the solution to restoring it, however, you may encounter problems as you go. Let's discuss them.

Surface Defects: Cracks and Chips

Issue: During the course of time, concrete garage floors can develop surface defects such as cracks, chips, and general wear and tear because of heavy foot and vehicle traffic, temperature fluctuations, and general wear and tear. Not addressing these imperfections in a timely manner can result in further damage.

Solution: Minor cracks can be repaired with concrete crack filler. A concrete patching compound can be used for larger cracks or chips. Ensure that the area is thoroughly cleaned before applying any repair material, and make sure all loose debris has been removed. Upon completion of repairs, we recommend resurfacing with a durable garage floor coating material.

Uneven Surfaces

Issue: There are several reasons why garage floors may be uneven. Incorrectly installed substrates can lead to concrete settlement issues. Soil movement is another occurrence. In addition to looking unsightly, an uneven surface can cause slips, trips, and falls.

Solution: There are numerous options you can choose from based on the severity of the issue. Consider self-leveling concrete overlays, concrete grinding services, or renting a concrete grinder from a local hardware store like Home Depot. Surface irregularities of moderate severity can be corrected with self-leveling overlays, whereas major unevenness is best addressed with grinding. Apply a durable resurfacing material such as epoxy resin, polyaspartic flooring, or polyurethane sealants after leveling the floor to ensure a smooth, long-lasting finish.

Stains and Discoloration

Issue: It is very common for garage floors to be stained by chemicals, oil, grease, and other substances. Discoloration can occur from deeply embedded stains, which can be difficult to remove over time.

Solution: Cleaning the concrete garage floor with a degreaser and stiff-bristle brush is the first step. Consider using a commercial-grade concrete surface cleaner for stubborn stains. Protect the floor from future staining and discoloration by applying an epoxy, polyaspartic, or polyurethane for floors after the stains have been removed.

Moisture Problems

Issue: The presence of excessive moisture can result in a range of problems with garage floors, such as damage to the concrete itself, mold growth, and efflorescence.

Solution: Any underlying moisture issues must be addressed before resurfacing your garage floor. A moisture test can be conducted to determine the amount of moisture present. Using concrete moisture meters, you can assess the moisture content of concrete slabs. To prevent moisture from seeping through concrete, moisture barriers or vapor retarders will need to be installed. Concrete slabs can be protected from moisture vapor and moisture entry with moisture vapor barrier coatings.

Delamination or Peeling

Issue: Existing garage floor coatings will peel or delaminate over time when detached from their concrete substrate. Typically, this problem results from inadequate surface preparation, poor-quality coating materials, or insufficient bonding.

Solution: If your concrete garage floor is peeling or delaminating, we recommend grinding or sanding the entire surface to fix the problem. The best way to accomplish this task is to use a small grinder for concrete or a hand held grinder. You must then clean, repair any damage, and make sure there is no moisture on or beneath the surface. To ensure proper application, choose a garage floor epoxy of high quality and compatibility. By preparing the surface properly and using suitable materials, peeling or delamination can be prevented in the future.

Choosing the Right Garage Floor Coating

You want your garage floor resurfacing project to be durable and long-lasting, so choosing the right material is crucial. There are several options available, including:

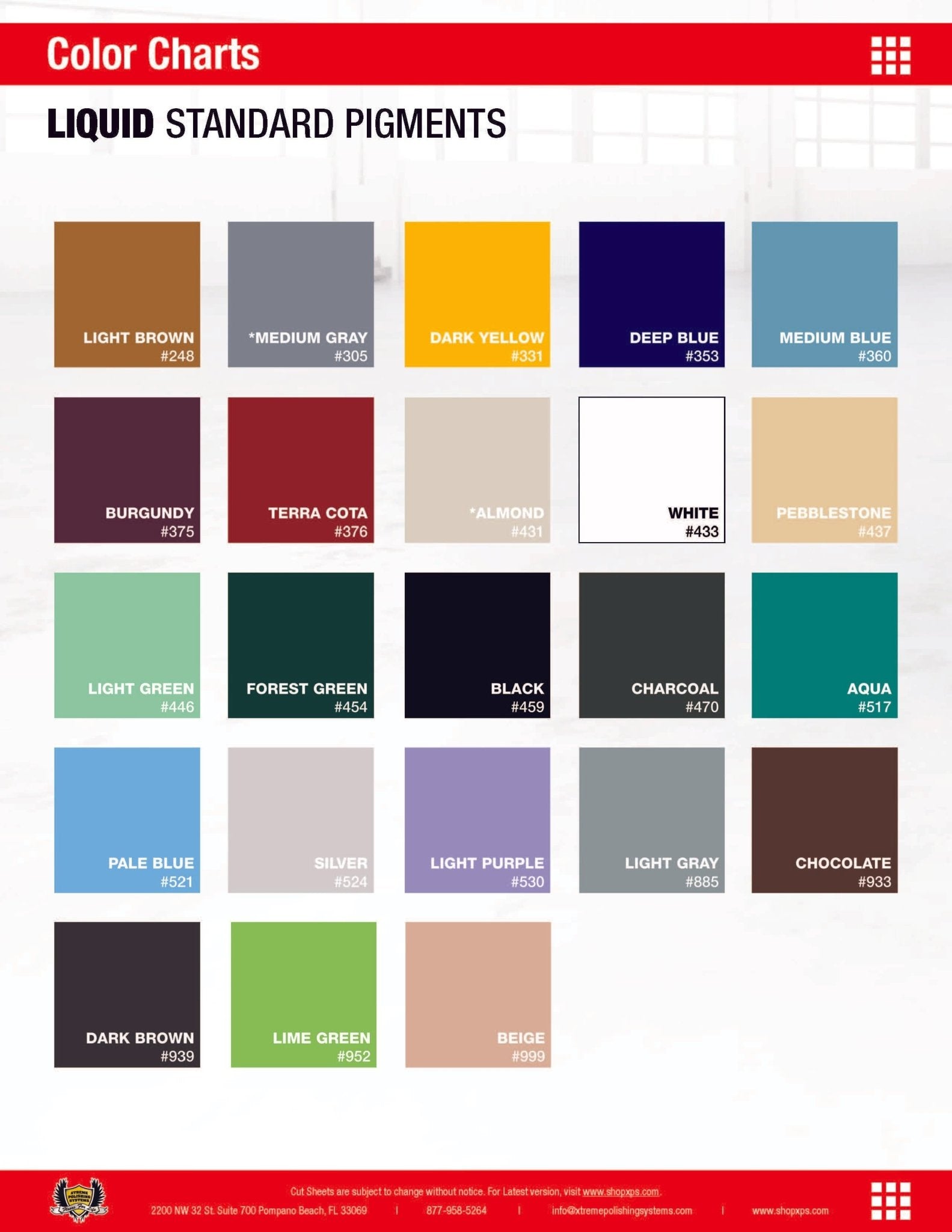

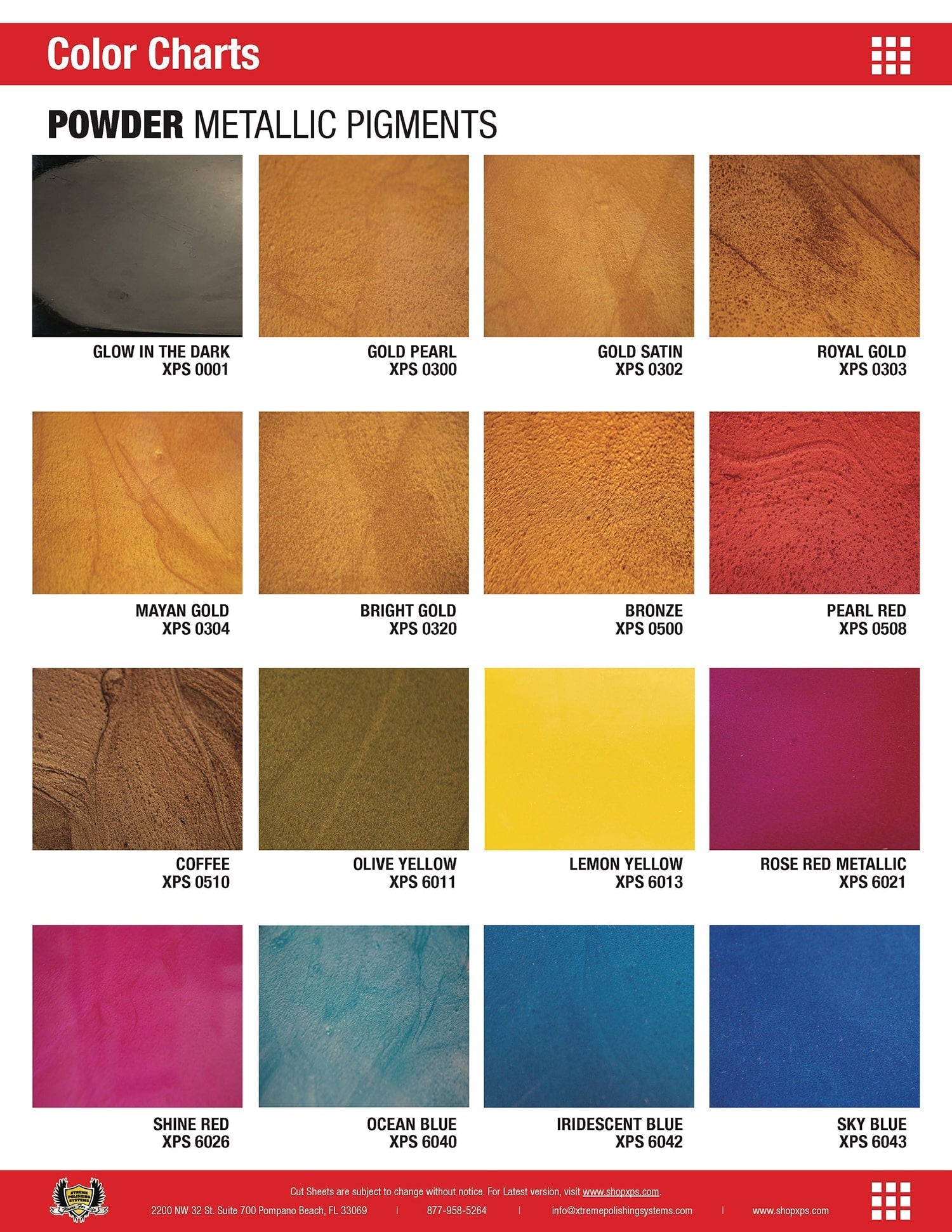

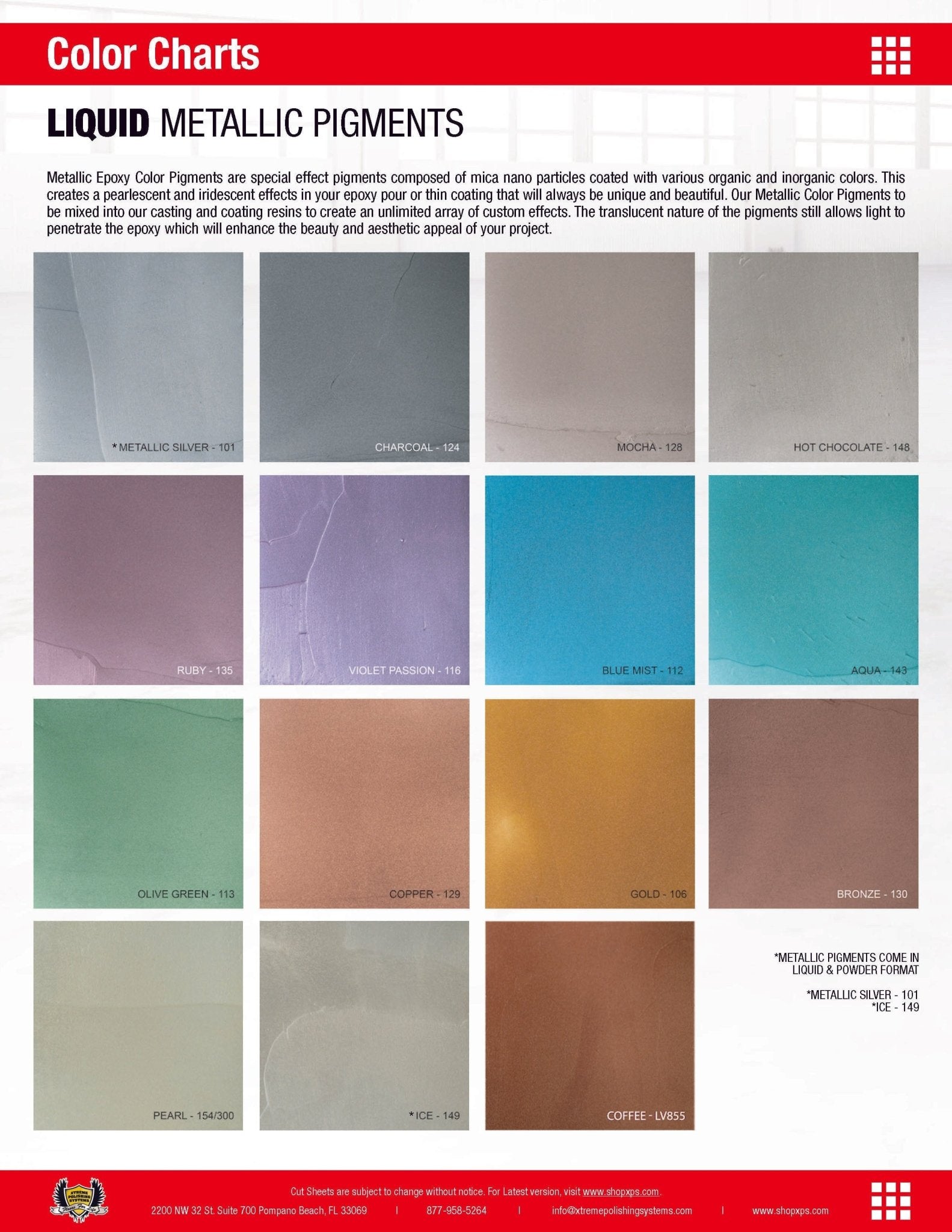

- Epoxy Garage Flooring - Epoxy coatings produces a smooth, glossy finish while being durable, long-lasting, and chemically resistant. With epoxy you can choose from an array of decorative styles, including metallic, solid color, and glitter finishes.

- Polyaspartic Floor Coatings - This durable material can be applied at a variety of temperatures, is UV-stable, and chemical-resistant. Its high performance features makes this material perfect for garage settings.Flake and quartz systems are the ideal finishes to use with polyaspartic coatings.

- Polyurethane Flooring - Similar to polyaspartic, polyurethane features excellent abrasion resistance, UV stability, and flexibility, making it an ideal choice for garage floors that experience temperature fluctuations.

If you are thinking about resurfacing your concrete garage floor, be sure to consider your specific needs and preferences. To find out what product would be best for your garage floor project, consult a product specialist.

Conclusion

To summarize, resurfacing your concrete garage floor is essential to maintaining its safety, functionality, and aesthetic appeal. Garage floor coating is a durable and long-lasting resolution that meets your needs and expectations when common problems are addressed and appropriate solutions are implemented.

If you have any questions about garage floor resurfacing, please do not hesitate to contact one of our professionals.