Modern technology has made it possible for you to quickly achieve a showstopping concrete floor to enhance the aesthetic value of your spaces. Although laborious, you are probably more excited thinking about getting started on revamping your current concrete substrate than the actual work it entails.

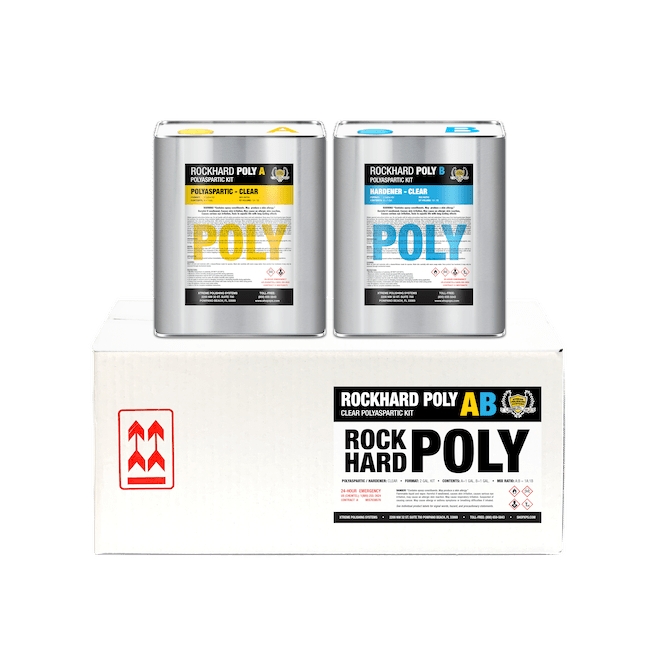

Concrete floor finishes, such as epoxy coatings, decorative overlays, and polished concrete applications all require surface preparation. Often, improper or inadequate concrete surface preparation results in early wear, flaking, or other floor defects.

What is Surface Preparation?

Simply put, Surface Preparation is the process of prepping a concrete surface for an application by preparing its surface through a series of steps. As a result, the concrete surface becomes clean and level, free of dirt, dust, and oils, which allows new materials to be applied directly. Concrete is thus given more surface area and roughness, which allows a stronger bond to be achieved between the surface and the concrete finish that is installed.

The dangers of poorly prepared concrete surfaces can appear almost instantaneously after completion. Although, ensuring that your concrete floor provides a stable foundation for your new finish does not have to be a time-consuming operation. Therefore, you cannot overstate the importance of professional surface preparation in ensuring the longevity of your floor.

The Primary Methods for Surface Preparation

The primary steps for Surface Preparation will be determined by the concrete, exposure, and the finishing technique that you choose. Even still, you should always remove any dust, filth, grease, and surface matter before starting a concrete floor finish.

The following methods are fundamental for Surface Preparation:

Inspect the Surface

Inspecting the surface means determining the strength and moisture content of the concrete. Despite its seemingly insignificant nature, skipping this step would negatively impact the adhesion of surface applications. In other words, you must eliminate anything that will hinder your job before installation.

Moisture Mitigation

Cleaning and leveling the surface of a concrete substrate in preparation for a final floor finish is typically required, as is addressing moisture mitigation issues.

Concrete flooring, especially, has the potential to break over time due to exposure to wetness or extreme humidity levels. That is why moisture mitigation technologies should get installed. Moisture mitigation innovations are utilized on job sites by industry professionals every day to ensure that moisture will not be an issue in the future.

In addition to testing moisture levels, it’s important to test for oil and grease, which will have an effect on the method used to clean the surface. Some methods, such as acid etching, are ineffective at removing these contaminants, and should not be used when they are present.

In most cases, if water droplets bead up on the concrete surface, either oil, grease, or some sealing agent is present on the surface and will need to be removed. These tests should be backed up by more rigorous testing that measures condensation on plastic film if there is any doubt about moisture content.

Concrete Surface Cleaning

While sweeping and mopping are acceptable methods of cleaning concrete, concrete can be difficult to maintain, especially because of its porous nature. Dust and dirt can easily accumulate on concrete.

It is vital that dust, dirt, debris, cured materials, oil, and grease are removed from surfaces before any coating or surface application is applied, otherwise, it will not adhere properly. It may be necessary to use specific cleaning agents to remove grease and chemical stains.

Effective concrete cleansers successfully cut through grease, oil, and tenacious spoilage. Choosing a technique for profiling the surface must take care that the clean surface is not re-contaminated.

Powerful janitorial machines like high-speed propane and electric burnishers, floor buffers, and floor scrubbing equipment are also precisely constructed for regular floor maintenance and floor cleaning applications.

Concrete Profiling

In general, concrete profiling involves smoothing down rough concrete surfaces in preparation for future applications. The procedure may require the use of heavy-duty concrete floor grinding machines and diamond-impregnated grinding segments that mimic sturdy sandpaper. A variety of advantages can be obtained from concrete profiling, which is a long-term investment.

Concrete Surface Repair

Once the concrete is ground smooth, any protrusions need to be repaired. If there are cracks in the concrete, they should also be patched.

Cracked or damaged concrete surfaces can be repaired with joint fillers and repair products. Filler products like this were specifically developed for creating chemical interactions with the host material (concrete). It is important to choose joint filler and surface repair products that are long-lasting, water-resistant, and chemical-resistant.

There are a number of joint fillers and surface crack fillers offered by Xtreme Polishing Systems, all of which can be used in both epoxy and concrete applications and are designed to fill and repair cracks and joints in residential, commercial, and industrial settings.

The Importance of Surface Preparation

Floor finishes are only as strong as the substrate to which they are applied. Hence, if you invest your well-earned money in new flooring, you should make sure it will last. It is significantly more cost-effective to properly prepare a surface from the start rather than having to reinstall your floor finish after it fails.

The majority of issues that can arise from poor surface preparation occur because the surface you are putting on top is only as good as the one beneath it. As a result, the integrity of the surface you are installing on is critical.

Removing remaining mastic, glues, or grouts from a prior flooring installation is one method used by experts to prepare the concrete surface. Experts can also restore damage if necessary. They also treat any contaminants and impurities, such as oils, drywall mud, or even dampness prevalent in the existing concrete.

In addition, skilled personnel grinds the floor to reach the desired CSP for the new flooring surface. Ultimately, surface preparation protects the final floor finish, whatever its type, whether carpets, coatings, overlays, or something else.

Conclusion

Although these steps may seem minor, skipping them could negatively impact the adhesion of surface coatings. Skipping these steps may seem minor, but skipping them will negatively affect the adhesion of the coating on the surface.

Surface Preparation can be one tedious, overwhelming job. But, who said that you must do it manually on your own? Xtreme Polishing Systems can avail a large fleet of surface preparation, decorative concrete, and floor polishing equipment, tooling, and materials for residential and commercial concrete flooring needs. With their pool of experts and state-of-the-art line of machinery and supplies, prepare to have your ideal concrete finish a reality!