What is a Concrete Sealer?

Concrete sealer is a finishing product that’s applied after the surface has been polished. Concrete sealer is considered the finishing layer in providing protection, while enhancing and preserving the appearance of the floor’s surface. With so many different sealers and brands on the market, it is extremely important to know which type of sealer to use to complete each specific flooring project:- Topical Sealers: provide visual enhancement and topical protection from stains and chemicals. This type of sealer requires a dry, clean surface during application to gain the proper adhesion. Topical sealers may alter the coefficient of friction which can make the substrates slippery when wet – a condition that can easily be fixed by adding anti-skid materials.

- Penetrating Sealers: applied to dry or damp surfaces, this type of sealer should be properly matched with substrate porosity in order to effectively penetrate the surface and react. The chemical reaction bonds active ingredients within the substrate blocking surface moisture. Penetrating sealers generally do not significantly modify substrate appearance or traction.

- Acrylic Resins: forming a topical film membrane on the substrate surface, this type is available in both water-based and solvent-based formulas, affordable, and are generally simple to apply. Being well known to increase perceived visual enhancement (sometimes described as a “wet look”) and providing adequate UV protection for colored substrates. Despite being the softest and least lasting of the major sealers, price and convenience make acrylic resins a very popular choice for decorative concrete.

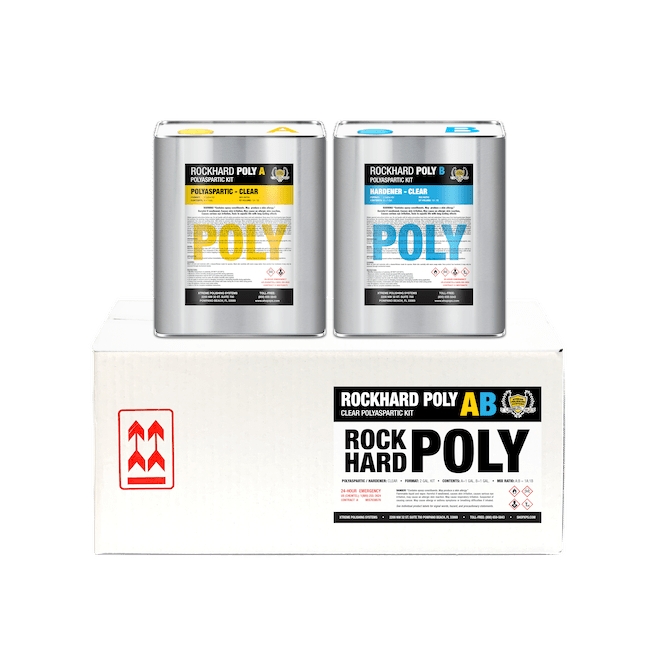

- Epoxy/ Urethane Systems: the performance levels and life span are superior and typically more costly with much more complex installation requirements. High-end urethanes are also known to be extremely abrasion resistant. Epoxy/ Urethane Systems are frequently used in demanding applications such as factory floors, garage floors, and restaurants.